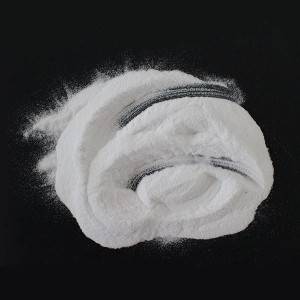

This product is one of the most widely used catalyst carriers,according for about 70% of industrial supported catalysts.Alumina has many kinds of crystalline form and different characteristics.Even the same form has different properties depending on its different origin,such as density,pore structure and specific surface area.

Specification of general catalyst carrier

|

TY401 |

TY402 |

TY403 |

TY404 |

TY405 |

||

|

외관 |

물에 불용성 화이트, 구, 아니 냄새, 무해한 |

|||||

|

크리스탈 유형 |

XP에서 |

XP에서 |

와이 |

와이 |

XP에서 |

|

|

화학적 구성 요소 |

알 2O 3 % |

≥93 |

≥93 |

≥93 |

≥93 |

≥90 |

|

나트륨 2O % |

≤0.3 |

≤0.3 |

≤0.5 |

0.15-0.3 |

≤0.3 |

|

|

LOI |

% |

6-8 |

6-8 |

≤8 |

≤5 |

6-8 |

|

부피 밀도 |

g / ㎖ |

0.68-0.72 |

0.70-0.75 |

0.65-0.75 |

0.70-0.80 |

0.68-0.72 |

|

표면적 |

m 2/ g |

≥300 |

≥300 |

250-280 |

≥280 |

≥350 |

|

기공 부피 |

㎖ / g |

0.30-0.45 |

0.30-0.42 |

0.40-0.46 |

0.40 |

0.30-0.50 |

|

정적 흡수 (RH는 = 60 %) |

% |

수분 흡수 |

불소 흡수 |

수분 흡수 |

수분 흡수 |

수분 흡수 |

|

유효한 |

% |

56-62 |

||||

|

마찰 손실 |

% |

≤1.0 |

≤1.0 |

≤1.0 |

≤0.4 |

≤0.8 |

|

파쇄 강도 (N / 입자) |

0.4-1.2 |

≥30 |

||||

|

1-2 |

≥40 |

≥40 |

||||

|

2-3 |

≥60 |

≥60 |

||||

|

3-5 |

≥100 |

≥100 |

≥100 |

≥100 |

||

|

4-6 |

≥120 |

≥130 |

≥120 |

≥110 |

||

|

5-7 |

≥160 |

|||||

|

6-8 |

≥180 |

|||||

물리적 특성

TY401: is for as adsorbent

TY402: is for defluorinating

TY403: is for absorption in producing hydrogen perixide (H2O2)

TY404: is for catalyst carrier

TY405: is for dehydrating and drying in air seperation etc