Activated Alumina use exclusively in different industries for water absorbent. It is available in granules 2-6 mm in size & spheres / Balls 2-5 mm in size.

Its application in different industries as follows:

|

INDUSTRIES |

APPLICATION |

|

FERTILIZER |

Instrument air drying |

|

CRYOGENIC |

Gas drying |

|

CHEMICALS |

Oil vapour removal from compressed air drying of oxygen plant |

|

PETROLEUM聽 REFINING |

Instrument air drying |

|

PETROCHEMICALS |

Removal of acidic & ionic impurities from Alkylation Feed stocks Organic liquid drying (benzenexy聽 lene etc) |

|

FOOD AND PHARMACEUTICALS |

Instrument air drying Dehumidification system |

|

MINERAL OIL INDUSTRIES |

Transformer / insulation oil Transformer winding drying |

|

REFRIGERATION |

Drying of refrigerants such as freon |

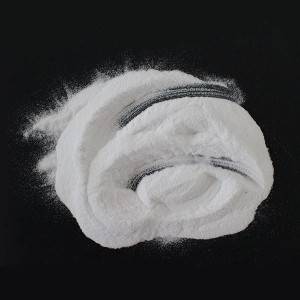

White Aluminium Oxide Physical Properties And Chemical CompositionBrief Introduction Of White Aluminium Oxide

white aluminum oxide was made from the high quality aluminum oxide by melting above 2000 in the electric arc furnace and cooling. It is white with the main crystal phase alpha-Al2O3.The aluminum oxide produced in titling electric arc furnace has the advantage of high bulk density and low porosity and the volume stability and thermal shock resistance can be improved.

|

white aluminium oxide physical properties |

||

|

1 |

Color |

White |

|

2 |

Hardness: Mohs |

9.0 |

|

3 |

Bulk density |

1.75-1.95 g/cm3 |

|

4 |

Specific Gravity |

3.95g/cm3 |

|

5 |

Melting Point |

2250℃ |

|

6 |

maximum operation temperature |

1900℃ |

|

white aluminium oxide chemical analysis |

||

|

1 |

Total Al2O3 |

≥99.3% |

|

2 |

Total Fe2O3 |

≤0.05% |

|

3 |

TotalNa2O |

≤0.03% |

|

4 |

Total CaO |

≤0.02% |

|

5 |

Total K2O |

≤0.01% |

|

1 |

Sandblasting Lapping, polishing |

|

2 |

Surface treatment/finishing |

|

3 |

Bonded abrasives and Coated abrasives |

|

4 |

sand blasting in the process of TV screen |

|

5 |

Ceramic Tiles special ceramics |

|

6 |

Fluidized Bed Furnaces and Skin / Dental Care |

|

7 |

Grinding high carbon steel, high-speed steel and chilled steel |

White Aluminium Oxide Applications